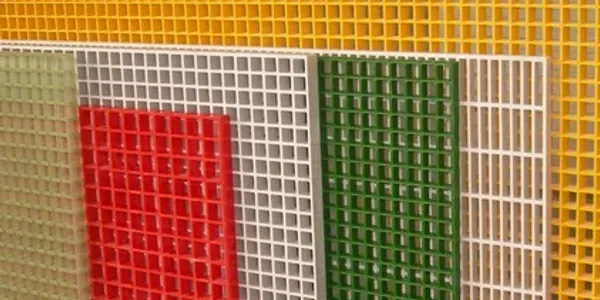

FRP Fencing

FRP fencing offers a modern, durable, and low-maintenance solution for a wide range of applications. Its superior properties, including corrosion resistance, lightweight strength, and aesthetic versatility, make it an ideal choice for industries, coastal areas, public infrastructure, and agriculture. As technology advances and sustainable practices evolve, FRP fencing will continue to be a leading option in fencing solutions, providing long-lasting and reliable performance.

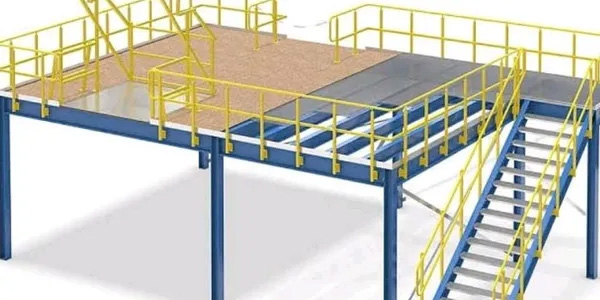

FRP Handrail

FRP handrails offer a superior alternative to traditional handrail materials, providing unmatched durability, corrosion resistance, and low maintenance. Their wide range of applications, from industrial sites to public infrastructure, showcases their versatility and effectiveness. As technology advances and sustainable practices become more prevalent, FRP handrails will continue to be a leading choice in handrail solutions, ensuring safety and reliability in various environments.

FRP Handrail Fittings

FRP/GRP handrail fittings and connectors are the perfect solution for connecting and securing bridge railings and stair guardrails due to their various angles and types. These fittings are known for their exceptional anti-aging properties, lightweight nature, and high strength, which ensure maximum stability of the handrails. Common types of FRP/GRP handrail fittings include round base flanges, adjustable fittings, square bases, and others. Additionally, they offer a visually appealing appearance.

FRP Grating

Unlike standard gratings available on the market, our FRP moulded gratings are renowned for their superior chemical and corrosion resistance. These gratings are celebrated for their remarkable durability and extended lifespan, which have revolutionised industries traditionally reliant on wood, concrete, or metal products that tend to deteriorate rapidly. By offering a more resilient and long-lasting alternative, our FRP moulded gratings address the challenges faced by conventional materials and set a new standard in the industry.

Benefits of Pultruded FRP Profiles

Strength and Durability

Pultruded FRP profiles are renowned for their high strength-to-weight ratio, making them ideal for load-bearing applications without adding excessive weight. .;

Corrosion Resistance

FRP materials offer excellent resistance to chemicals, moisture, and extreme temperatures, ensuring longevity even in harsh environments.

Design Flexibility

The pultrusion process allows for the creation of complex shapes and custom profiles, catering to specific design and structural requirements.

Revolutionizing Infrastructure with Pultruded FRP Composites

High Strength-to-Weight Ratio

Pultruded fiberglass offers an exceptional strength-to-weight ratio, making it an ideal choice for load-bearing applications without adding unnecessary weight. This attribute is particularly beneficial in construction, where structural integrity and ease of handling are crucial.Corrosion and Weather Resistance

Fiberglass composites are inherently resistant to corrosion, moisture, and UV radiation. These properties ensure long-term durability and minimal maintenance, even in harsh environmental conditions.Electrical and Thermal Insulation

Pultruded fiberglass provides excellent electrical insulation and low thermal conductivity. This makes it suitable for applications where electrical and thermal properties are critical, such as in utility poles and HVAC systems.Design Versatility

The pultrusion process allows for the creation of complex shapes and custom profiles. This design flexibility enables architects and engineers to develop innovative solutions tailored to specific construction needs.CONTACT US

Superior FRP Handrail Systems for Optimal Safety and Durabil

Our expertise lies in supplying high-strength, maintenance-free handrails that suit a variety of applications, from small platforms to complex structures. Discover the durability and reliability of our handrails, designed to meet your specific needs with unmatched performance.

Understanding FRP Handrail Systems

FRP (Fiberglass Reinforced Plastic) Handrails are engineered to provide exceptional mechanical properties, making them ideal for various environments. These handrails are assembled using FRP Pultrusion, SMC connectors, and stainless-steel fasteners, ensuring they are lightweight, corrosion-resistant, and impact-resistant. Designed in accordance with OSHA and building code standards, our FRP Handrails guarantee safety and compliance.Key Benefits of FRP Handrails:

- High Corrosion Resistance: Perfect for harsh environments where traditional materials fail.

- Impact Resistance: Withstands significant impact, ensuring long-term durability.

- Lightweight: Easy to handle and install, reducing labor costs.

- Low Maintenance: Requires minimal upkeep, saving you time and money.

FRP Handrail System Process

Our FRP Handrail system process is meticulously designed to meet industry standards and exceed customer expectations. Here’s a detailed look at our process:- Consultation and Assessment: We begin with a thorough consultation to understand your specific needs and site requirements.

- Sourcing High-Quality Materials: We procure top-quality FRP components from reliable and trusted suppliers to ensure the highest standards of safety and durability.

- Custom Design: Our team designs a tailored FRP Handrail system, ensuring it meets all relevant safety and building codes.

- Installation: Our skilled technicians install the handrails efficiently, ensuring a secure and stable setup.

- Inspection and Quality Assurance: We conduct a final inspection to ensure everything meets our rigorous quality standards.

Types of FRP Handrail System Services

We offer a variety of FRP Handrail systems to cater to different needs:- Square Type Handrails: Ideal for industrial settings requiring robust and durable handrails.

- Round Tube Type Handrails: Perfect for commercial applications with an emphasis on aesthetics and functionality.

FRP Grating: Superior alternative to traditional materials

In today's industrial landscape, the demand for durable and reliable materials is ever-increasing. One such material that has gained significant attention is Fiber Reinforced Plastic (FRP) grating. Known for its strength, durability, and versatility, FRP grating is becoming the go-to solution for various industries. Here, we delve into the extensive range of FRP grating offered by Delta, highlighting its benefits, applications, and why it stands out from traditional materials.

Cost-Superior Quality and Manufacturing Excellence Solutions

Delta prides itself on providing an extensive range of FRP grating, meticulously manufactured using superior-quality FRP materials and advanced techniques. Each piece of grating undergoes stringent quality checks to ensure durability and reliability, making it a preferred choice for several industries. The superior quality control measures guarantee that Delta's FRP grating meets the highest standards, providing long-lasting solutions for demanding environments.Wide Range of Industrial Applications

FRP grating is widely used across various industries due to its exceptional properties. It finds applications in the chemical industry, petrochemical industry, food processing industry, mineral industry, and cement industry. The versatility of FRP grating makes it suitable for a range of environments where other materials may fail to perform effectively.Competitive Pricing and Cost-Effectiveness

In addition to its high quality and versatility, Delta offers FRP grating at competitive prices, making it an economical choice for businesses. The cost-effectiveness of FRP grating lies not only in its initial price but also in its long-term benefits, such as reduced maintenance and longer lifespan compared to traditional materials.Competitive Pricing and Cost-Effectiveness

In addition to its high quality and versatility, Delta offers FRP grating at competitive prices, making it an economical choice for businesses. The cost-effectiveness of FRP grating lies not only in its initial price but also in its long-term benefits, such as reduced maintenance and longer lifespan compared to traditional materials.Unmatched Benefits of Delta’s FRP Grating

- Corrosion Resistance: One of the standout features of Delta's FRP grating is its corrosion resistance. Unlike steel or aluminum gratings, which can deteriorate in harsh environments, FRP grating remains unaffected by corrosive substances, ensuring a longer lifespan and reduced maintenance costs.

- Lightweight and Easy Installation: FRP grating is significantly lighter than traditional materials, making it easier to handle and install. This lightweight nature not only reduces labor costs but also minimizes the risk of installation-related injuries.

- Zero Maintenance: Once installed, Delta's FRP grating requires minimal to no maintenance. Its resistance to corrosion, weathering, and chemical exposure ensures that it remains in excellent condition without the need for frequent upkeep, further reducing overall costs.

- Durability and Longevity: Delta’s FRP moulded grating offers unparalleled durability. Its uniform cross-section, resin dispersion, and fiber distribution and alignment contribute to its strength and longevity. In highly corrosive atmospheres, Delta's grating can outlast steel by up to 20 times, making it a wise long-term investment for industries where frequent grating replacement is impractical.

- Ideal Solution for Corrosion Problems: For industries grappling with corrosion issues, Delta's FRP moulded grating presents an ideal solution. Its superior design and material composition ensure it withstands the harshest conditions, providing a reliable alternative to steel or aluminum gratings. This makes it particularly beneficial in industries where exposure to corrosive elements is a significant concern.